In the world of brewery equipment, the whirlpool sedimentation tank stands as a crucial component, ensuring efficient separation of wort and promoting quality beer production. Let’s delve into its structural and technical requirements to grasp its importance.

Structural Design and Functionality

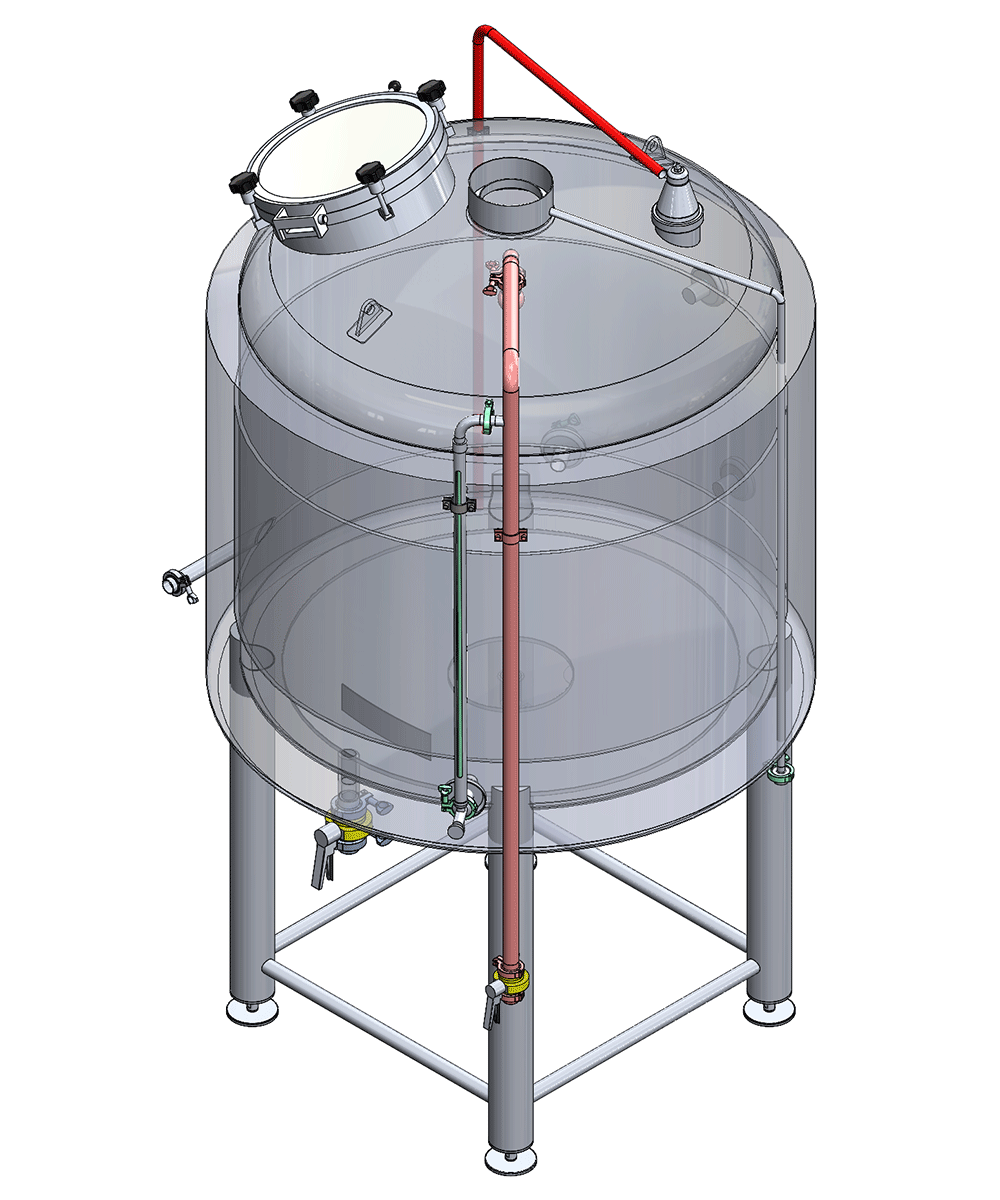

The whirlpool sedimentation tank is a cylindrical container with a flat bottom, designed to optimize the separation process of wort. Here’s a breakdown of its key features:

- Inlet Design: Wort enters the tank tangentially, minimizing oxygen absorption. Typically, there are two inlets—one at the bottom and another at a higher level—to facilitate effective mixing without disrupting the sedimentation process.

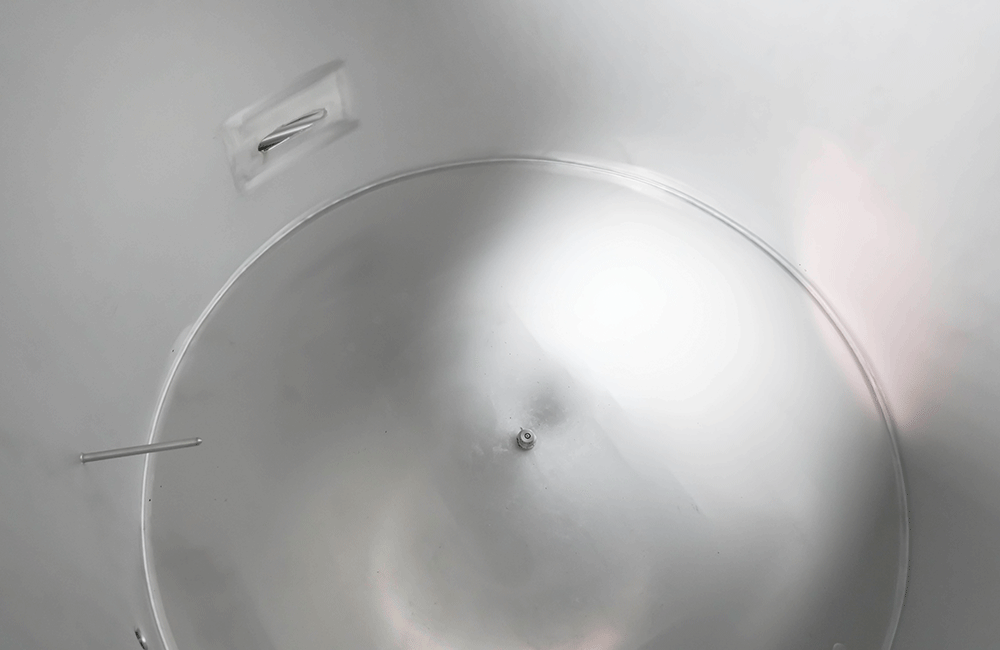

- Internal Configuration: The tank’s interior must be smooth and free of obstructions like cooling pipes or manhole doors protruding inward. Such objects can cause turbulence, compromising the separation efficiency.

- Height-to-Diameter Ratio: This ratio (H/D) plays a critical role. A ratio of 1:3 is commonly preferred, balancing sedimentation areas with thermal coagulation requirements. A larger H/D ratio results in lower wort volume, enhancing separation effectiveness.

- Outlet Placement: Wort outlets are strategically positioned on the side near the tank bottom. Their placements ensure a sequential discharge from top to bottom, preventing turbidity caused by rapid flow impact.

- Cleaning and Maintenance: After wort discharge, the tank is cleaned using clean water to remove sediment. Depending on the tank’s design, sediment may accumulate in a conical collection cup or on a slightly sloped bottom for easier removal.

Technical Considerations

Insulation: Modern tanks often feature insulation layers to maintain wort temperature and prevent cooling during the sedimentation process.

Water Spray System: An integrated water spray ring pipe aids in tank cleaning, ensuring hygienic conditions between brewing cycles.

Air Duct Shield: A flat windshield at the air duct outlet prevents wort oxidation, crucial for maintaining beer quality.

Practical Applications

In practical brewery operations, understanding these structural and technical aspects ensures optimal performance of the whirlpool sedimentation tank. It facilitates efficient wort separation, contributing to the overall quality and consistency of brewed beer.

Conclusion

The whirlpool sedimentation tank exemplifies precision engineering in brewery equipment, blending practical design with technical finesse. Its role in ensuring a clear separation of wort underscores its significance in modern brewing processes. For breweries considering equipment upgrades or new installations, mastering these tank dynamics is pivotal for achieving brewing excellence.

Refequency questions

10BBL Double Wall Conical Beer Fermentation Tank

1000L stainless steel steam heating beer equipment

12BBL steam heating mashing beer equipment