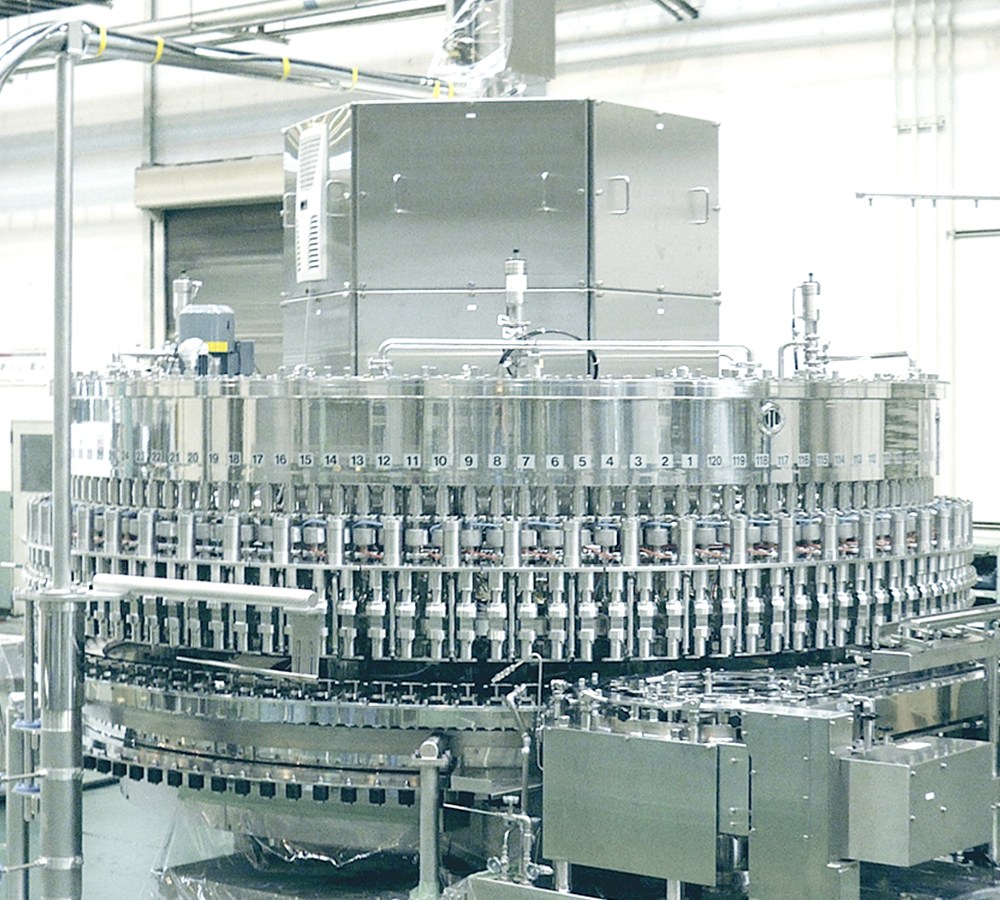

Brewery Setup Blog

Do something for your dream.

Start from selection

We believe strongly that we can and must do something different.

Our aim is to make your ideas come true.

Our aim is to make your ideas come true.

Location

CN Jinan- 2668

Jichang Rd.

Email Us

Call Center

24/7 Support

+86 531 88161066

Request A Quote